A solid case can protect your delicate objects, but it’s the custom case foam insert that will cradle each piece and hold it securely.

The types of foam used in protective cases each have distinctive qualities and best uses. But with a wide foam selection, how do I know which is best for my case? Like what are the differences between polyurethane and polyethylene foams? Well, the experts at Production Case have you covered!

The right foam for your Pelican case will keep your gear safe and secure when you’re on the road. It’s a good idea to have an understanding of the types of foam options available before you choose a case to protect your valuables.

Contact Us Today! Give Us A Call

Let’s go over each of the foam types we offer and how they differ:

- Standard Polyurethane Foam

- Convoluted (Egg Crate) Polyurethane Foam

- Standard Polyethylene Foam

- Cross-Linked Polyethylene Foam (XLPE)

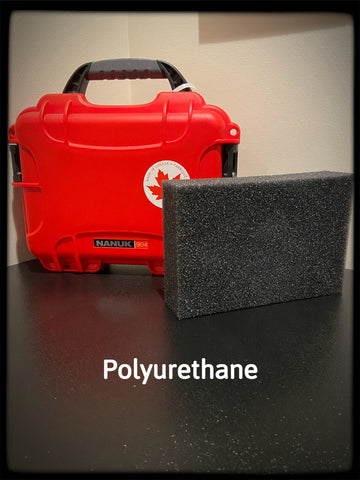

1. Standard Polyurethane Foam

Description: Polyurethane foam is soft and squishy foam that is best used for cushioning lighter items. It provides excellent shock absorption and is used for our standard pick-and-pluck foam inserts.

Custom polyurethane foam inserts are available, but you can also DIY with a utility knife. Polyurethane foam is a good option for cameras, electronic components, and anything glass or delicate.

Benefits:

-

Soft and cushioning

-

Ideal for lightweight equipment

-

Easy to cut and customize

-

Affordable and widely available

-

Open cell foam

Texture: Soft, lower density, sponge-like, flexible foam.

2. Convoluted (Egg Crate) Polyurethane Foam

Description: Convoluted polyurethane foam, often called egg crate foam, has a wavy, egg crate pattern that distributes pressure evenly. It is also soft and squishy as it’s made from polyurethane.

The egg crate-shaped design has empty spaces between the foam sections, letting it easily absorb impact. Convoluted polyurethane foam is best used for electronics, fragile equipment, and case lid inserts.

Benefits:

-

Lightweight cushioning, best for evenly distributed pressure

-

Ideal for delicate items

-

Provides airflow and prevents moisture buildup

Texture: Soft, sponge-like, flexible.

3. Standard Polyethylene Foam

Description: Polyethylene foam, while still having some give, is firmer than polyurethane foam. It’s often used for heavier equipment that needs firm support. It’s also more durable and water resistant, dampens vibrations, and insulates well.

Standard polyethylene foam can be machined to specific depths, giving you tailored foam case inserts that are very precise. It’s a great option for firearms and heavier equipment that can absorb shock. It's also classified as an anti-static foam, which is imperative for protecting electronics.

At Production Case, we sell ready-made "Hard Layered Foam Sets" made to fit the insides of different Pelican cases. We also have 1" Hard Foam Lining Kits with PE foam for all the inner walls and lid of the case.

Benefits:

-

Excellent impact resistance

-

Ideal for heavier or high-value equipment

-

Closed cell foam

Texture: Firm and dense with a smooth surface.

4. Cross-Linked Polyethylene Foam (XLPE)

Description: Considered the “Ferrari” of foams, XLPE foam is a premium version of polyethylene foam, with better durability, a softer touch, and an incredibly smooth surface, like a mix between rubber and foam surface. It is often used for presentation cases and high-end protective inserts. XLPE foam is the best option for high-value, sensitive, and heavier instruments, firearms, and gear that need top-of-the-line protection.

"Zote" is the popular brand of XLPE foam we carry.

Benefits:

-

Superior impact protection

-

Water and chemical resistance

-

Professional appearance

-

Closed cell foam

Texture: High density and smooth.

Choosing the Right Foam for Your Case

The best foam depends on what you need to protect, and your budget. You’ll want to think about the weight and value of the items you’re storing. How easy is it to break? For delicate electronics, polyurethane or convoluted foam works well. For heavier tools or firearms, polyethylene or XLPE foam provides better protection.

Custom Foam Inserts: Protect Your Gear Perfectly

Need precise protection with zero jostle? Foam inserts can be custom tailored for your equipment. Watch this video to see how custom foam inserts are created.

Protect Your Equipment with Production Case

Choosing the right foam for your protective hard will help keep your valuable equipment safe. Think about whether you need firm, water-resistant polyethylene or soft, cushioning polyurethane, or if custom tailored inserts are the right way to go.

At Production Case, we carry Pelican, Nanuk or SKB protective hard cases for everything from firearms to camera and medical EMS cases. When you order a case with foam, the standard foam is soft layered or cubed polyurethane foam.

We have a range of foam types and colours available on request. And for custom foam inserts, get CNC precision using your own design files or take full advantage of Production Case Company's in-house design team.